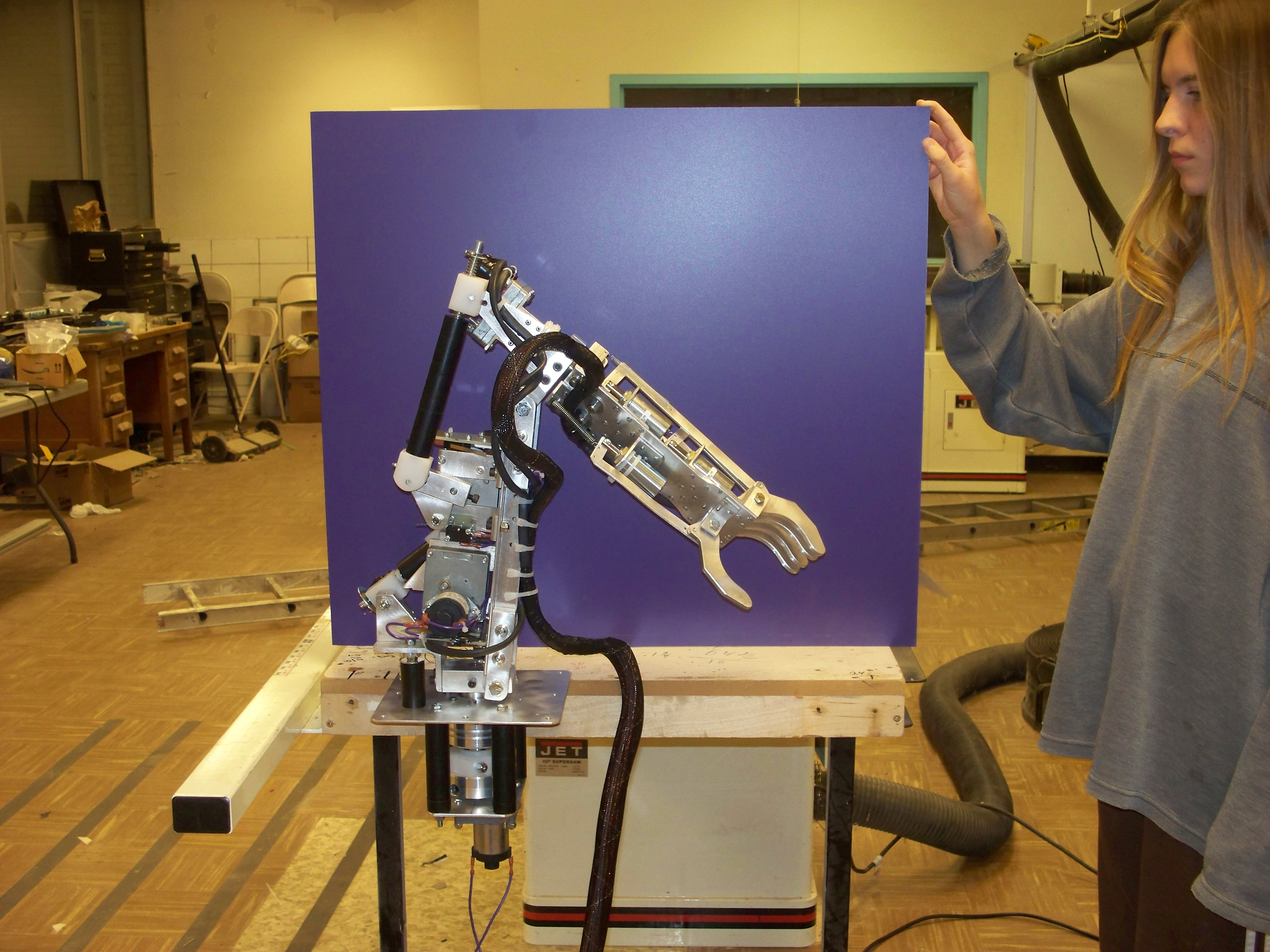

Early Prototypes And Current Designs

Robot hands built from wood, springs, and rubber bands marked the first experiments at Shadow Robot in the late 1990s, according to company director Rich Walker. At the company’s north London headquarters, newer versions now use cylindrical forearms that house small electric motors, known as actuators, which pull on metal tendons to move fingers with precision. The hands are controlled through sensors strapped to a user’s fingers. During demonstrations, the movements are smooth and controlled rather than erratic. Around 200 of these hands are in use, mostly by researchers at universities and technology companies. Walker said the hardware acts as a development platform for studying dexterity and for planning larger systems or deployments, adding that such work is needed because most tools and devices are designed for human hands.

Why The Hand Remains A Bottleneck

Bren Pierce, founder of Bristol-based robotics company Kinisi, said the hand is the hardest and most complex part of any humanoid robot. His company is testing 10 KR1 robots in commercial settings and fits them with different grippers depending on tasks. He said strong pincers are used for heavier items, while suction devices handle more delicate work. Pierce said the goal is a single hand flexible enough to handle many tasks. Kinisi has built a three-fingered hand that he described as effective, but he said the remaining problems are durability, large-scale manufacturing, and cost. The prototype hand costs about £4,000, compared with about £400 for the simpler pincer the company currently uses.

Industry Attention And Public Claims

The difficulty of building such a hand was highlighted by Elon Musk at the All-In Summit in Los Angeles in September last year, when he listed it as one of three major challenges for humanoid robots, alongside artificial intelligence that can interpret the world and the ability to manufacture robots at scale. Musk has said Tesla’s Optimus robot, expected to be released this year, will have manual dexterity comparable to a human. Nathan Lepora, professor of robotics and AI at the University of Bristol, said that level of dexterity is not imminent and estimated it could take about 10 years. He is working on a project under the UK government’s Aria research and development program and, like Shadow Robot, focuses on tendon-driven hands. He said more advanced tendon systems could lead to more affordable and capable designs.

Different Approaches From Chinese Firms

Lepora said he has also been watching progress in China, where companies are placing motors directly into fingers and joints instead of using tendons. He said manufacturers there are designing custom motors that fit within joints and fingers, which could lead to practical results. Shanghai-based Wuji Technology is one of those companies. Its latest hand gives each finger four independently controlled joints, allowing more complex movement. Co-founder Yunzhe Pan said the hand is designed for durability and that the next generation will be more durable. The current version sells for about $12,000, and Pan said the company plans to lower the price over time. The hand uses piezoelectric sensors that convert pressure into electrical signals, giving it a sense of touch.

Durability And Sensing Challenges

Developing reliable touch sensing remains a major task. Pierce said many research labs and start-ups have advanced sensors that work for only about six months, which he said is suitable for research but not for industrial use, where equipment is expected to last for years. Lepora said tactile sensing has long seemed close to maturity but out of reach, though he said large investments in humanoid robots are starting to change the pace of progress.

Featured image credits: Wikimedia Commons

For more stories like it, click the +Follow button at the top of this page to follow us.