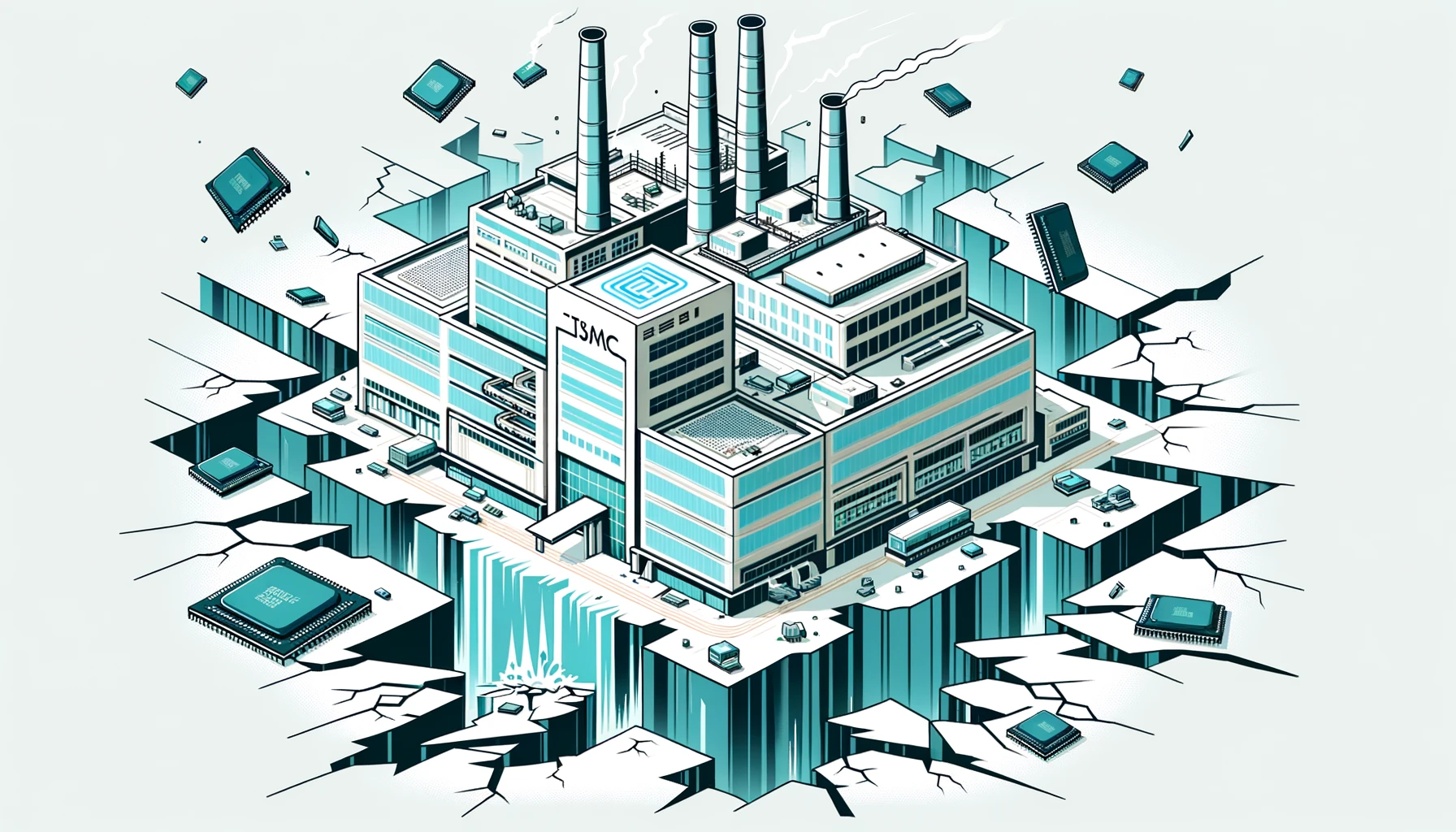

In the aftermath of a seismic event that rocked Taiwan, the world braces for potential disruptions in the supply of semiconductors, sending shockwaves across industries reliant on electronic devices. The 7.4 magnitude earthquake, striking Taiwan, a crucial hub in the global technology supply chain, has prompted fears of price hikes and shortages in mobile phones, PCs, and various electronic gadgets.

The earthquake, the most powerful to hit Taiwan in 25 years, has forced major semiconductor manufacturers to halt operations and evacuate personnel. Companies such as Taiwan Semiconductor Manufacturing Co. (TSMC) and United Microelectronics Corp. (UMC), vital players in the production of advanced chips, have been compelled to shut down sections of their facilities, raising concerns about the continuity of chip manufacturing.

Estimated Impact on Semiconductor Production

| Company | Operational Status | Impact on Production | Assessment of Impact |

|---|---|---|---|

| TSMC | Partial shutdown | High | Ongoing evaluation |

| UMC | Ceased operations | Significant | Evaluating extent of impact |

Bullet Points:

- TSMC, serving as a primary contract chipmaker for tech giants like Apple and NVIDIA, has faced disruptions as it relocated staff and evaluated the earthquake’s impact.

- UMC, another key player, suspended operations at various plants in Hsinchu and Tainan, contributing to the uncertainty in chip supply.

- Taiwanese firms, including TSMC and ASE Technology Holding Co., dominate the global semiconductor market, supplying chips for diverse applications ranging from smartphones to automobiles.

- Approximately 80-90% of silicon chips worldwide originate from Taiwan, making the country a linchpin in the global semiconductor supply chain.

Taiwan’s geographic location near a major fault line makes it susceptible to frequent and potent earthquakes, posing inherent risks to semiconductor production. The concentration of semiconductor manufacturing in Taiwan has long raised concerns among industry leaders and government officials regarding supply chain vulnerabilities.

The COVID-19 pandemic exacerbated existing semiconductor shortages, underscoring the fragility of global supply chains. Industries worldwide grappled with a scarcity of chips, driving up prices and exacerbating challenges for manufacturers and consumers alike.

The semiconductor shortage prompted price hikes and facilitated scalping activities, particularly in high-demand sectors such as gaming and cryptocurrency mining. Products like NVIDIA’s GPUs witnessed significant price inflation, with scalpers exploiting market dynamics for profit.

Government officials worldwide have urged Taiwanese companies to diversify their manufacturing locations to mitigate risks associated with reliance on a single geographic region. Concerns over Taiwan’s stability, compounded by its proximity to China and susceptibility to natural disasters, have spurred calls for strategic diversification in semiconductor production.

The earthquake in Taiwan serves as a stark reminder of the fragility of global supply chains, particularly in the semiconductor industry. As the world grapples with the aftermath of this seismic event, stakeholders must prioritize resilience and diversification to mitigate risks and ensure the stability of critical supply chains. In the face of mounting geopolitical tensions and natural disasters, collaborative efforts are imperative to safeguarding the continuity of global technological innovation.

Related News:

Featured Image courtesy of DALL-E by ChatGPT